How to Make Your Own Computer Chip, Part 3

This was not originally intended to be an ongoing series when I started writing about it in November 2023, but a lot has happened with the open source silicon movement in the intervening time. I was lucky enough to make another trip up to the Bay Area for Open Sauce 2025 to see what is going on with it now.

The Open Sauce 2025 logo etched onto some wafers for semiconductor manufacturing. The bottom wafer has also been “doped”, albeit not using the type of toxic chemicals the real manufacturing process would require.

The biggest new development in open source silicon fabrication is easily the development of the HackerFab blueprint for creating a working chip fab in a garage, university research lab, or similar. The instructions for that concept can be found here: https://docs.hackerfab.org/home

The project has some pretty ambitious goals:

Make integrated circuit prototyping as fast as 3D printing

Make DIY version of every nanofabrication tool

Get there with collaborative open source hardware

Relatively none of the first part has been achieved, but the second two pieces seemed to be in a state of rapid progress at Open Sauce 2025, where my good friend John McMaster had helped to organize a booth under the FOSSF (Free Open Source Silicon … SF?) umbrella. There he had a spherical chicken level approximation of the $200 million ASML TwinScan machine on display, affectionately dubbed the “TwimSkan”.

The workflow for the TwimSkan machine as assembled in the booth seemed to be something like, a robot arm could theoretically grab a wafer and move it into position for a stand with a projector and industrial grade optical laser to do the etching. From there, a human with a tweezers could deposit the wafer in a spin coater (i.e. a 3D printed centrifuge) with a few drops of photoresist analog (nontoxic dye). In a real world flow the spin coater would put dopant on the wafer and then the wafer would be brought up to a high temperature in a tube furnace. Another contributor to the FOSSF booth, Edmond, had bought a prototype of a tube furnace to display at the event.

So what was actually working out of all the equipment in the booth? A couple of dozen wafers had already been laser etched in advance of the event. I personally used the spin coater to deposit some dye on one of them and bring it up to speed. Cool stuff. The robot arm was working, but connectivity issues in the convention center made its operation somewhat complicated. The tube furnace also worked, though that couldn’t be demonstrated at Open Sauce due to safety concerns.

Running the HackerFab spin coater at Open Sauce 2025.

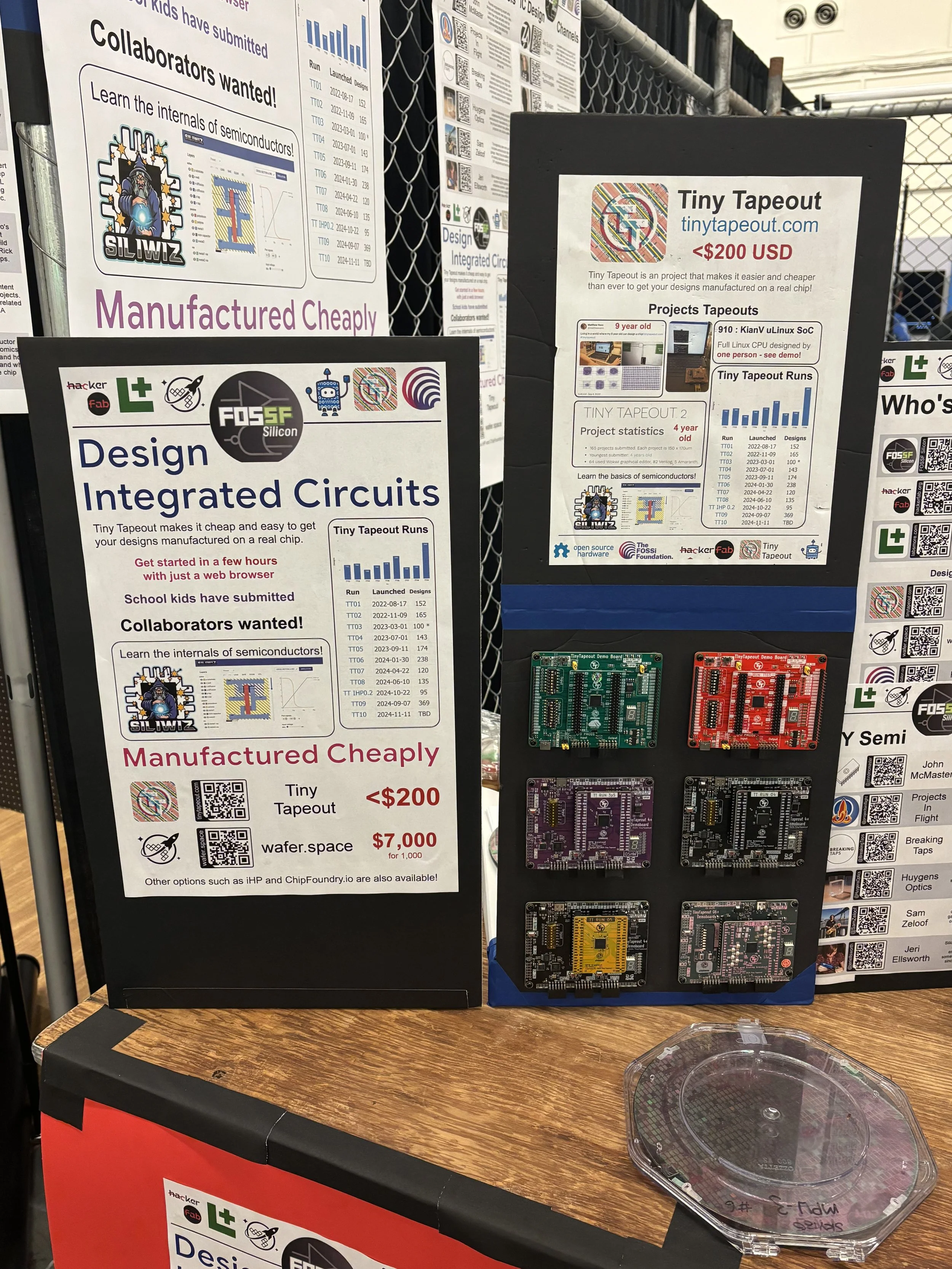

Meanwhile Tim Ansell was also on hand evangelizing a separate initiative, Tiny Tapeout, which HAS NOT SHUT DOWN, and a similar but more commercialized venture called wafer.space. These are less of a DIY project and more of a way for people to be able to purchase access to existing commercial fabs. TinyTapeout has mainly targeted students and hobbyists looking for a first experience taping out a chip, whereas wafer.space seems to be aimed more at companies that need to be able to manufacture something at a bit higher level of scale.

It costs around $200 per person to participate in TinyTapeout as it is right now, though Tim seemed to believe that the price of participation could be brought down to around $70-80 if more people were interested in joining each shuttle. The projects that people have submitted to TinyTapeout have ranged in complexity from school projects to running Linux or Doom in the roughly 10,000 gates provided per chip.

The TinyTapeout project lives to see another day, and an exhibit at Open Sauce 2025.

Overall it seems like a pretty promising time to be interested in open source silicon technology. The biggest hurdle to further development is easily just the cost of buying the hardware. To make a crude analogy, buying a 3D printer would probably be about a $20 Walmart toaster oven while setting something like this up would be more like having a $1500 Ooni pizza oven. Almost everyone can justify spending $20 on something if they really want to spend $20. Spending 75 times that is a really difficult decision for a lot of people because you have to answer harder questions like, what is the end product going to be? How often will I really use this?

Still, it seems a little bit like any of the experiments where scientists have claimed to have generated microbacterial life just by having the correct conditions in a terrarium. At some point, people will figure this out, the same way SpaceX made rocket launches easy, or Waymo is making driving a task for robots. It’s not impossible: the impossible barrier is slowly being cleared. It’s just expensive.

Latest track (“dubai matcha morning rave”)